Quality Control Checklists are used in construction to ensure proper execution of tasks and compliance with technical requirements.

The main purpose of these checklists throughout a project’s phases is:

- to identify and document defects

- to evaluate work quality vs the stablished standards

- to record changes

- to also serve as a tool for training field staff and subcontractors, pushing for a shared understanding of quality standards.

- as a firewall mechanism when drawing the line between contract scopes with subcontractors.

What are the differences between punch lists and checklists?

- A punch list in construction is a document used to record and track the final tasks, corrections, or improvements that need to be completed before a construction project is considered finished or “punched out.” Therefore, punch lists only record defects.

- Quality Control Checklists are lists that are built (prepared before execution) that summarise the quality criteria that the built item has to comply with. Upon completion, the checklist will have all its inspection points approved or passed.

The advantages of the Checklists are evident in their comprehensive documentation, aiding construction companies in tracking work, identifying defects, and providing guidance in case of disagreements with clients.

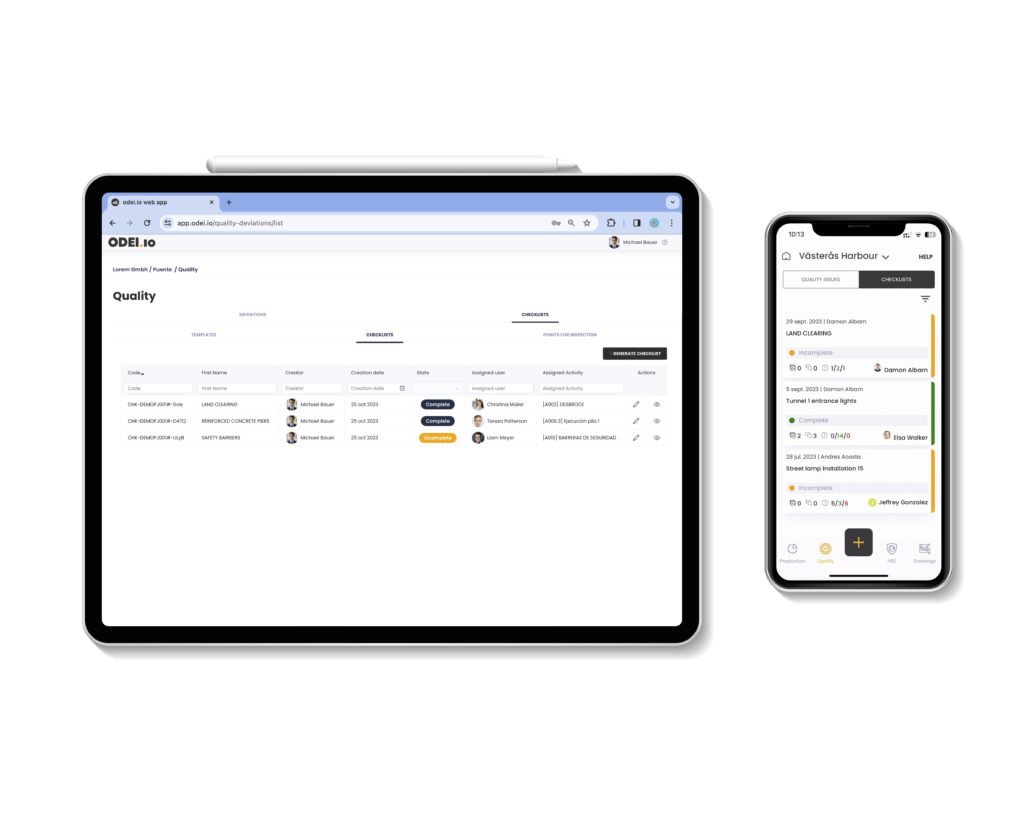

Digital checklists are increasingly favoured for their accessibility, flexibility, and ease of use, allowing real-time updates from various devices.

Let’s see some differences:

What are the top 5 disadvantages of having quality checklists in paper or excel?

The main disadvantage of using paper quality checklists in construction is the potential for inefficiency and limitations in accessibility and collaboration.

Here are some key drawbacks:

- Limited Accessibility: Paper checklists are physically bound and can be in only one place at a time. This can make it challenging for different team members, especially those working in various locations on a construction site, to access and update the checklist simultaneously.

- Delayed Updates: Making changes or updates to a paper checklist requires manual effort, and distributing the revised version to all relevant parties can lead to delays. This can result in team members relying on outdated information, potentially causing misunderstandings or mistakes.

- Data Management Challenges: Retrieving specific information from paper records can be time-consuming. Searching for details or trends within a checklist may be difficult compared to digital alternatives, which often provide search and filter functionalities.

- Limited Collaboration: Collaborative efforts are restricted with paper checklists. Team members may find it challenging to contribute or share real-time updates, which is crucial for effective communication and problem resolution in construction projects.

- Difficulty in Analysis: Analysing data and trends from paper records may be more labor-intensive compared to digital formats. Digital checklists often offer features for automated data analysis, which can provide valuable insights into the overall quality performance of a construction project.

What are the top 5 advantages of using digital quality checklists?

Switching to digital quality checklists in construction offers several advantages over traditional paper methods:

- Enhanced Accessibility: Digital checklists provide instant access to team members working in different locations on a construction site. This real-time accessibility ensures that everyone is on the same page, contributing to better coordination.

- Instant Updates: Changes and updates to digital checklists can be made in real-time. This ensures that all team members have access to the latest information promptly, reducing the risk of relying on outdated records.

- Efficient Data Management: Digital checklists often come with search and filter functionalities, making it easier to retrieve specific information. This streamlines the process of managing and analyzing data, saving time and effort.

- Improved Collaboration: The collaborative nature of digital checklists facilitates communication among team members. They can contribute, share updates, and address issues in real time, promoting a more efficient and cohesive working environment.

- Streamlined Analysis: Digital checklists often come equipped with features for automated data analysis. This makes it easier to analyze trends and performance metrics, providing valuable insights into the overall quality of the construction project.

Quality Control Checklists are crucial in preventing errors during construction, facilitating thorough quality checks, complete documentation, and aiding in training and communication.

That clear, implementing a digital tool for managing the quality inspections will bring efficiency and quality to your project.